Wholesale Fine Mist Spray Bottles | Custom Manufacturer

Explore Our Spray Bottles and Mist Bottles Collection

Not finding what you're looking for?

Contact our consultants for more available products.

The Art of the Mist: Redefining Product Application

A superior spray bottle does more than just dispense liquid; it atomizes it, creating a sensory experience that elevates your product's performance and perceived value. Discover the distinct advantages of our precision-engineered spray bottle technology, designed to delight customers and protect your formulations.

Ultra-Fine, Cloud-Like Mist

Our advanced atomizer engines are engineered to produce a consistent, ultra-fine mist that feels soft and gentle on the skin. This ensures an even, delicate application without large droplets, providing a luxurious and refreshing experience for toners, facial mists, and setting sprays.

Continuous & All-Angle Spraying

Designed for ultimate convenience, many of our spray bottles feature technology that allows for continuous spraying and full 360° all-angle use—even upside down. This provides a seamless and effortless application, perfect for body sprays, hair mists, and sunscreens.

Hygienic, Contact-Free Application

The spray mechanism offers a completely contact-free application, reducing the risk of transferring bacteria from hands to the face or product. This hygienic benefit is especially crucial for sensitive skin formulations, toners, and products designed to be used throughout the day.

Enhanced Formula Efficacy & Coverage

An ultra-fine mist provides superior surface area coverage, allowing your formula's active ingredients to be absorbed more evenly and efficiently by the skin. This enhances the overall efficacy of your product, ensuring your customer receives the full benefit with every spray.

The Engineering of a Perfect Mist: How Our Atomizers Work

Transforming a liquid into a cloud-like mist is a science of precision. A high-performance fine mist sprayer is not just a pump; it’s a sophisticated atomizer engine designed to break down liquid into millions of micro-droplets. The quality of the mist—its fineness, consistency, and spray pattern—is determined by the hidden engineering within the pump head.

The Piston & Pre-Compression Chamber

When the actuator is pressed, a piston moves to create pressure. Before the liquid is released, it's forced into a tiny pre-compression chamber. This crucial step builds up the necessary pressure to ensure the liquid will be expelled with high velocity, which is the first requirement for creating a fine mist rather than a simple jet of water.

The Swirl Chamber & Vortex Creation

From the pre-compression chamber, the high-pressure liquid is channeled into a uniquely designed swirl chamber. The geometry of this chamber forces the liquid into a rapid, spinning vortex—similar to a miniature cyclone. This spinning action is the secret to breaking the liquid's surface tension.

The Orifice: Final Atomization & Spray Pattern

The final step is the exit. The spinning, high-velocity liquid is forced through a precisely molded orifice (the tiny hole at the tip of the nozzle). As the vortex exits this small opening, it shatters into millions of uniform, micron-sized droplets, creating the soft, ultra-fine mist that evenly coats the skin. The shape of this orifice is what defines the final spray pattern (e.g., a wide cone).

Need Custom Packaging Solutions?

Precision Sprayers: Your Technical Selection Guide

Mist Quality: Droplet Size & Spray Pattern

The “feel” of a mist is a science. It’s determined by the size of the liquid droplets (measured in microns) and the shape of the spray cloud. A premium mist is exceptionally fine and evenly distributed, while a poor-quality sprayer produces large, wet droplets in an inconsistent pattern.

- Droplet Size (Atomization): Our high-performance atomizers are engineered to produce an average droplet size of 50-80 microns, creating a soft, cloud-like mist that feels gentle and absorbs quickly, rather than a harsh, wet spray.

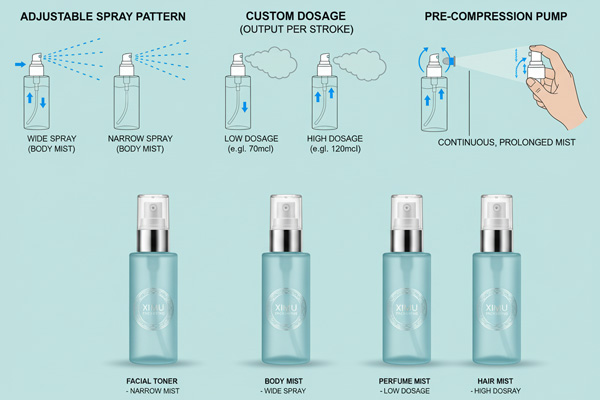

- Spray Pattern & Angle: We can customize the spray pattern by engineering the orifice geometry. Whether you need a wide, enveloping cone for a body spray or a narrower, more targeted mist for a facial toner, we match the pattern to your product’s intended use.

The Pump Engine vs. Your Formula's Viscosity

A common point of failure is a mismatch between the sprayer’s engine and the product’s formula. Even a slight increase in viscosity can dramatically affect mist quality, or cause the pump to clog or fail entirely.

- Viscosity Matching is Critical: Fine mist sprayers are designed for water-like liquids (typically under 10 cps). We always advise testing your specific formula with our sprayer samples.

- Specialized Engines for Thicker Formulas: For slightly more viscous products (like some lightweight serums or hair mists), we can recommend specialized “high-viscosity” sprayer engines that are designed to handle them.

- Ingredient Compatibility: Certain ingredients, especially some essential oils, can cause swelling or degradation of internal plastic components over time. Our experts help you select the right polymer materials for your formula’s long-term stability.

Dispensing Technology: Pre-Compression vs. Standard

This is a key technical difference that defines the user experience. A standard sprayer delivers mist only while you are actively pressing down, but advanced options offer a more continuous and controlled application.

- Standard Sprayers: Cost-effective and reliable for most applications. The spray duration and pressure are directly controlled by the user’s finger motion.

- Pre-Compression Sprayers (Continuous Mist): This advanced engine builds up pressure inside the chamber before releasing the mist. The result is a prolonged, ultra-fine, and completely consistent spray that continues even after you’ve stopped pressing. It’s a premium feature ideal for luxury setting sprays, hair mists, and body sprays.

Priming, Leak-Proofing, and Long-Term Reliability

These small details are crucial for a frustration-free consumer experience from the first use to the last.

- Efficient Priming: Our pumps are designed with efficient valves and pistons to ensure the sprayer is “primed” (starts spraying) with minimal initial pumps.

- Secure Sealing: The cap and pump assembly are meticulously tested for a perfect, airtight seal to prevent leakage during shipping and travel, a common failure point for low-quality sprayers.

- Durable Components: We use high-quality springs and robust polymers for the internal engine to guarantee tens of thousands of actuations without a decline in performance, ensuring the sprayer works reliably throughout the product’s entire life.

Ready to Create Your Perfect Spray Bottles and Mist Bottles?

{acf_ideal_applications_h2_title}

{acf_ideal_applications_application_intro}

Custom Spray Bottle Solutions: Engineered for Your Brand & Formula

Transform your unique vision into a high-performance spray bottle. Our comprehensive OEM & ODM customization services allow you to tailor every component—from the internal atomizer engine to the external aesthetics—creating a signature packaging solution that delivers a flawless mist and embodies your brand.

Fast & Flexible Customization, Made Simple.

{acf_packaging_suggestions_h2_title}

Quality Assurance: Verifying Performance & Reliability for Fine Mist Sprayers

Spray Pattern & Atomization Analysis

This is our most critical test. Using specialized equipment, we analyze the spray pattern’s angle, uniformity, and average droplet size (atomization). We ensure the sprayer produces a consistent, ultra-fine mist, not a wet spray, guaranteeing the luxurious application your product deserves.

Pump Actuation & Life Cycle Test

Our atomizer engines undergo extensive life cycle testing, where they are actuated thousands of times by automated equipment. We measure actuation force and spring return speed to guarantee a smooth, effortless press and long-lasting, reliable performance throughout the product’s entire lifespan.

Leakage & Seal Integrity Test

Every bottle and sprayer combination is subjected to rigorous leakage tests under vacuum pressure and in various orientations (e.g., sideways, upside down). This ensures a perfect, airtight seal, guaranteeing your product is safe during e-commerce shipping and travel.

Formula Compatibility & Clogging Test

We test our pump engines with your specific formula (or a chemical simulant) to check for any long-term material compatibility issues with internal components like gaskets and springs. This also serves as a clogging test, ensuring your formula flows smoothly through the atomizer’s micro-channels without blockage.

Priming & Dispensing Consistency Test

A great user experience starts with the first spray. We test how many initial pumps are required to “prime” the sprayer and begin dispensing. We also verify the consistency of the spray output over multiple strokes to ensure a frustration-free initial use and a predictable application every time.

Fine Mist Sprayers: Technical & Sourcing FAQs

What is the main difference between a standard lotion pump and a fine mist sprayer?

The key difference is the internal “atomizer engine.” A fine mist sprayer contains a specialized swirl chamber and a precision orifice that work together to break down the liquid into millions of micron-sized droplets as it’s forced out under pressure. A lotion pump is designed to simply dispense a thicker product in a single stream.

What type of liquid formulations are suitable for your fine mist sprayers?

Our fine mist sprayers are designed for liquids with a low, water-like viscosity (typically under 10 centipoise). They are not suitable for thicker liquids, gels, or oils, which will clog the engine. We always recommend providing us with your formula for a compatibility and performance test.

Can the spray pattern (e.g., the width of the mist) be customized?

Yes. The spray pattern and angle are determined by the geometry of the pump’s final orifice. While many of our sprayers come with a standard, optimized pattern, we can work with you to select or develop an atomizer engine that provides a narrower or wider spray cone to perfectly suit your product’s intended application.

Are your spray bottles suitable for shipping via e-commerce?

Absolutely. Our spray bottles are designed with secure, tight-sealing closures and undergo rigorous leakage testing. Many models also come with a protective overcap that prevents accidental actuation during transit, making them a reliable choice for e-commerce brands.

What are the typical MOQs (Minimum Order Quantities) for custom spray bottles?

Our standard MOQ for spray bottles is typically 10,000 units. This can vary depending on the bottle, the complexity of the atomizer engine, and the level of customization required. Please contact our team with your project details for a precise quote.