Crystal-Clear & Recyclable PET Bottles | Wholesale & Custom

Explore Our PET Bottles Collection

Not finding what you're looking for?

Contact our consultants for more available products.

The PET Advantage: Clarity, Sustainability, and Performance

Polyethylene Terephthalate (PET) is one of the most trusted and versatile materials in the packaging industry. Choosing PET is a strategic decision that balances brilliant aesthetics, robust performance, and a strong commitment to environmental responsibility. Discover the key benefits that make our PET bottles a superior choice for your brand.

Glass-Like Clarity & Premium Aesthetics

Our high-quality PET bottles offer exceptional, crystal-clear transparency that beautifully showcases your product's true color, texture, and purity. This provides the premium look of glass without its weight and fragility, instantly elevating your brand's shelf presence and perceived value.

Lightweight & Shatterproof Durability

PET is renowned for being both lightweight and remarkably strong. This significantly reduces shipping costs and carbon footprint compared to glass. Its excellent impact resistance makes it shatterproof, ensuring a safer user experience in environments like the bathroom and reducing losses from breakage during transit.

Superior Recyclability & Sustainable Options

As one of the most recycled plastics in the world (Recycle Code #1), PET is a cornerstone of the circular economy. Choosing PET signals a commitment to sustainability. We further enhance this by offering high-content PCR (Post-Consumer Recycled) PET bottles, allowing your brand to reduce its reliance on virgin plastic and appeal to eco-conscious consumers.

Excellent Barrier & Formula Protection

PET provides a strong barrier against oxygen and moisture, which is crucial for protecting your product's integrity. This helps to preserve the efficacy of active ingredients, maintain the stability of the fragrance, and extend the overall shelf life of your valuable formulations, ensuring they reach your customers exactly as intended.

The Technology Behind PET: A Superior Material Choice

Polyethylene Terephthalate (PET) is more than just a clear plastic; it’s a high-performance polymer engineered for clarity, strength, and sustainability. Its unique molecular structure provides a combination of benefits that make it a technologically advanced and strategically sound choice for the world’s leading beauty and personal care brands.

Exceptional Clarity & Purity

The technology of PET manufacturing allows its polymer chains to align in a way that creates glass-like, crystal-clear transparency. This purity showcases your product's true color and texture without distortion, conveying a sense of quality and cleanliness that builds immediate consumer trust.

Superior Strength-to-Weight Ratio

PET is renowned for being both incredibly lightweight and remarkably strong and durable. This advanced strength-to-weight ratio means it requires less material to achieve high performance, which reduces shipping costs and environmental footprint. Its excellent impact-resistance also makes it shatterproof, ensuring safety in consumer environments like the bathroom.

Excellent Barrier Properties for Formula Protection

The tightly packed molecular structure of PET creates a strong barrier against oxygen and moisture. This technology is crucial for protecting the integrity of your formulations, helping to preserve the efficacy of active ingredients, maintain fragrance stability, and extend the overall shelf life of the product.

High Recyclability & PCR Integration

PET is one of the most recycled plastics globally (Recycle Code #1), making it a cornerstone of the circular economy. This high recyclability makes it an excellent sustainable packaging solution for environmentally responsible brands. Furthermore, PET is a key material used in the production of Post-Consumer Recycled (PCR) packaging, allowing brands to significantly reduce their reliance on virgin plastic.

Need Custom Packaging Solutions?

Overlooked Factors in PET Bottle Selection

Wall Thickness: The Key to a Premium, Glass-Like Feel

Not all PET bottles are created equal. The thickness of the bottle wall is a critical design choice that directly impacts the consumer’s perception of quality. While thin-walled PET is excellent for mass-market products, a heavier, thicker wall can elevate a PET bottle to feel as substantial and luxurious as glass, without the associated weight and fragility.

- Mimicking Glass: Heavy-wall PET provides a satisfying weight and a rigid structure that strongly conveys a premium positioning.

- Enhanced Durability: A thicker wall naturally increases the bottle’s strength and impact resistance, offering superior protection during shipping and handling.

- Brand Positioning: The choice of wall thickness is a key strategic decision. We can help you select the optimal thickness to align with your brand’s specific market positioning and price point.

PET vs. PETG: Choosing the Right Polymer for Your Formula

While visually similar, PET and PETG are different polymers with distinct advantages. Understanding this difference is crucial for ensuring long-term formula compatibility and performance, a detail that only experienced manufacturers emphasize.

- PET: An excellent all-rounder known for its exceptional clarity, lightweight nature, and strong barrier properties, making it a superior bottle material for a wide range of cosmetics.

- PETG: Offers superior impact resistance and enhanced chemical compatibility, making it a more suitable choice for certain complex formulas like gels and rich lotions. It also provides excellent UV resistance for light-sensitive products.

- Expert Advice: Our team will consult with you on your formula’s composition to recommend the precise polymer—PET or PETG—that guarantees the best performance and stability.

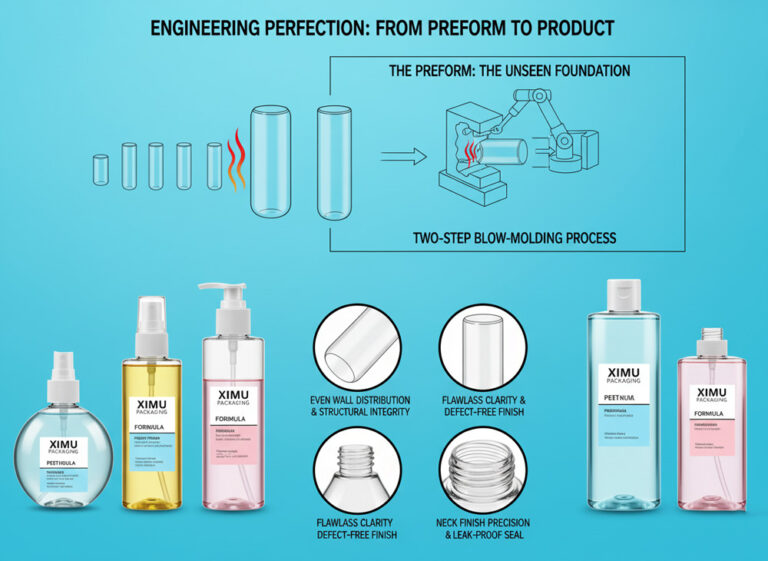

The Preform: The Unseen Foundation of a Perfect Bottle

This is a critical first-line production detail. PET bottles are formed in a two-step process where a “preform” (a small, thick test-tube-like shape) is first created, then heated and blow-molded into the final bottle. The quality and design of this unseen preform is paramount.

- Even Wall Distribution: A perfectly engineered preform is the secret to a final bottle with uniform wall thickness, preventing weak spots and ensuring structural integrity.

- Flawless Clarity: Any imperfections or impurities in the preform will be magnified in the final bottle. We ensure our preforms are pristine to achieve maximum clarity and a defect-free finish.

- Neck Finish Precision: The critical neck thread is perfectly formed during the preform stage, guaranteeing a perfect, leak-proof seal with your chosen cap or pump.

Surface Treatment: Ensuring Lasting & Premium Decoration

PET has a very smooth, non-porous surface, which can be challenging for inks and foils to adhere to permanently without proper preparation. Simply printing on raw PET can lead to logos and text scratching off easily.

- Essential Surface Preparation: To ensure your branding is durable, we employ essential pre-treatment processes (like flame or corona treatment) to prepare the bottle’s surface for decoration.

- Durable Branding: This extra step guarantees that your silk-screen printing or hot-stamped designs have maximum adhesion and will withstand the rigors of shipping and daily consumer use.

- Consultation is Key: We advise on the best decoration method for your chosen bottle finish (e.g., gloss vs. matte) to ensure a premium and lasting result.

Ready to Create Your Perfect PET Bottles?

{acf_ideal_applications_h2_title}

{acf_ideal_applications_application_intro}

Crafting Your Signature PET Bottle

Leverage the exceptional clarity and versatility of PET to create packaging that truly stands out. Our comprehensive OEM & ODM customization services allow you to tailor every detail of your PET bottle, ensuring a premium result that perfectly embodies your brand's aesthetic and values.

Fast & Flexible Customization, Made Simple.

{acf_packaging_suggestions_h2_title}

Quality Assured: Testing for Clarity, Strength, and Purity

Appearance Inspection

Each PET bottle is inspected under standard lighting conditions to check for any surface defects such as scratches, bubbles, or cracks. This inspection also verifies the consistency of color and transparency, ensuring a flawless, crystal-clear appearance that enhances your product’s value on the shelf.

Dimensional Accuracy & Assembly Fit Test

We use precision instruments to measure key dimensions, such as the bottle’s height and the diameter of the neck thread, to ensure they meet design specifications. This guarantees a tight and correct assembly fit between the bottle and your chosen cap or pump, which is fundamental to preventing leaks and ensuring reliable function.

Structural Integrity & Drop Test

To simulate the impacts of shipping and daily use, bottles are dropped from a specified height onto a hard surface. This test confirms the bottle’s robust structure and impact resistance, ensuring its durability and shatterproof quality during transportation and consumer handling.

Formula Compatibility Testing

We conduct compatibility tests by filling the PET bottle with the target product or a chemical simulant. This critical step checks for any adverse reactions, such as discoloration or material degradation, ensuring the packaging material is compatible with your product and will not compromise its quality or safety.

Leakage & Air Tightness Test

Bottles are placed under vacuum or pressure conditions to detect any potential for leakage or air ingress. This test verifies that the bottle and its seal maintain an airtight environment, which is crucial for protecting sensitive formulas from long-term oxidation and contamination.

PET Bottles: Your Technical & Sourcing Questions Answered

How recyclable are PET bottles?

PET is one of the most recycled plastics in the world, identified by the #1 recycling code. Its high recyclability makes it an excellent choice for brands focused on creating a circular economy and offering sustainable packaging solutions to their customers.

What is the difference between PET and PETG?

While visually similar, PETG offers enhanced properties for specific needs. PETG has superior impact resistance and may be more suitable for thick gels and lotions. It also provides excellent resistance to UV rays, which helps in preserving different chemical formulas under various conditions. Our experts can help you decide which material is best for your specific product.

Do clear PET bottles protect products from UV light?

Standard clear PET offers limited protection against UV light. If your formula contains light-sensitive active ingredients, we recommend two solutions: using an opaque colored PET bottle, or incorporating specialized UV-inhibiting additives into the clear PET material during production to protect your product’s integrity.

Is PET suitable for all cosmetic and skincare products?

PET is known for its excellent durability and is a great bottle material for a wide range of cosmetics. However, as with any packaging material, we always recommend conducting a compatibility test with your specific formula to ensure there are no adverse reactions over time, guaranteeing your product’s quality and safety.

Are your PET bottles available in PCR (Post-Consumer Recycled) versions?

Yes, absolutely. We are committed to sustainability, and our Post-Consumer Resin (PCR) cosmetic packaging is made from recycled plastics, including PET. Opting for PCR PET is a powerful way to reduce your reliance on virgin plastic and enhance your brand’s eco-friendly credentials.