Wholesale & Custom Lotion Bottles for Skincare & Body Care

Explore Our Lotion Bottles Collection

Not finding what you're looking for?

Contact our consultants for more available products.

Packaging That Delivers a Flawless Application, Every Time

A great lotion bottle does more than just hold your product—it enhances the daily ritual of application, delivering your formula with precision and elegance. Discover the key benefits of our thoughtfully engineered lotion packaging, designed for reliability, brand impact, and superior formula protection.

Precision Dispensing & Controlled Dosage

Our high-quality lotion pumps are the core of the user experience. They are engineered for a smooth, reliable action, delivering a consistent, controlled dose of lotion with every press. This prevents waste, ensures a clean application, and provides the satisfying performance your customers expect.

Elegant Design & Maximum Brand Impact

The right bottle tells your brand's story. Whether you choose the crystal clarity of PET to showcase your lotion's color, the modern appeal of opaque HDPE, or the luxury of Glass, our diverse shapes and finishes provide the perfect canvas to create a commanding shelf presence and a memorable brand identity.

Secure Closures & Formula Protection

Protecting your formulation is paramount. Our lotion bottles feature secure, leak-proof closures to ensure safety during shipping and travel. Many of our pumps also include a twist-to-lock mechanism, providing an extra layer of security and preserving the integrity and shelf life of your valuable lotions.

Versatile Material & Sustainable Options

We offer a wide array of material options to match your brand's values and formula requirements. Beyond standard plastics, most of our lotion bottle designs are available in high-content PCR (Post-Consumer Recycled) versions, allowing you to make a powerful statement about your commitment to sustainability.

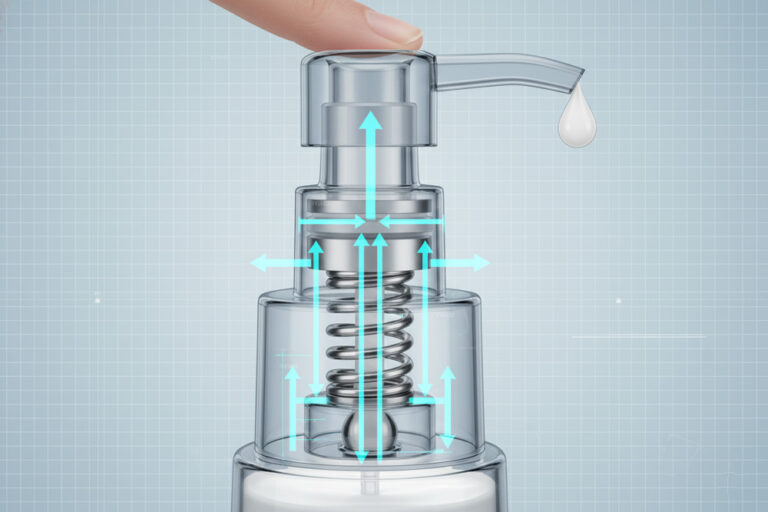

The Anatomy of a High-Performance Lotion Bottle

Lotion pump bottles operate on a classic and highly reliable atmospheric pressure system. When the pump is pressed, an internal piston and spring mechanism creates a pressure difference, drawing the lotion up from the bottom of the bottle through a dip tube. This product is then held in a chamber, ready to be dispensed through the nozzle on the next press. This proven system allows for consistent dosing, hygienic application, and excellent performance with a wide range of liquid and lotion viscosities, ensuring a dependable and satisfying user experience.

Actuator (Pump Engine)

The engine of the bottle, engineered for a smooth press and a precise, consistent dose.

Container (Bottle)

The vessel that protects your formula, available in various materials and shapes to represent your brand.

Dip Tube

The straw that reaches the bottom of the bottle, ensuring maximum product evacuation and minimal waste.

Need Custom Packaging Solutions?

Overlooked Factors in Lotion Bottle Selection

Matching the Pump Engine to Your Formula's Viscosity

A common mistake is assuming a “one-size-fits-all” approach for lotion pumps. A pump designed for a watery facial lotion will struggle with a thick body cream, leading to clogging, slow dispensing, or a poor user experience. The internal engine of the pump is a critical component that must be perfectly matched to your product’s specific thickness and properties.

- Viscosity Matching: We help you match your lotion’s specific viscosity to a pump with the correct engine, dosage chamber, and spring tension.

- Formula Testing: We strongly recommend testing your actual formula with our pump samples to validate a smooth, effortless, and consistent dispensing action before mass production.

- Metal-Free Path: For highly sensitive or acidic formulas, we can provide pumps with a “metal-free path,” where the lotion never comes into contact with the internal metal spring, ensuring absolute formula purity.

The Secret to a Clean, Drip-Free Nozzle

A premium user experience extends to the smallest details. A common issue with standard pumps is the small amount of lotion left at the nozzle tip, which can dry out, cause clogs, and look unhygienic. This small flaw can detract from a brand’s high-quality image.

- “Suck-Back” Valve Technology: We recommend high-quality pump heads that feature an integrated “suck-back” or “non-drip” valve.

- How It Works: This unseen mechanism gently retracts the tiny bit of leftover lotion back into the nozzle after each use.

- The Benefit: This keeps the orifice clean, prevents messy buildup, and guarantees a perfect, hygienic dose from the first use to the last, preserving a premium feel.

Choosing a Finish That Resists Fingerprints & Smudges

Trendy matte and soft-touch finishes feel luxurious, but they can be magnets for fingerprints, especially when used with emollient-rich hand or body lotions. A beautiful bottle can quickly look messy, which can negatively impact customer perception of your brand.

- Oleophobic (Oil-Resistant) Coatings: For matte finishes intended for body care, we can recommend specific oleophobic coatings that significantly reduce smudging from oily hands.

- Practical Gloss Finishes: For very oily products, a classic gloss finish is often a more practical and durable choice, as it is easy to wipe clean and maintains its premium look over time.

- Material Testing: We advise testing different finishes with your actual product to ensure the final choice aligns with both your brand’s aesthetic and practical, long-term use.

Protecting Active Ingredients with the Right Material

Many modern lotions contain active ingredients (Vitamins, Antioxidants, Botanical Extracts) that are sensitive to light. A beautiful clear bottle might showcase your product’s color, but it could also be compromising the formula’s stability and efficacy over time.

- Strategic Material Choice: This is a strategic trade-off. A crystal-clear PET bottle is excellent for showcasing the product, while an opaque HDPE bottle offers superior, built-in UV protection.

- UV-Blocking Solutions: For the best of both worlds, we can produce PET bottles with specialized UV-inhibiting additives or apply an opaque or translucent UV-blocking color coating.

- Expert Recommendation: For highly sensitive, “clean,” or preservative-free formulas, we generally recommend opaque materials to guarantee maximum protection and shelf life.

Ready to Create Your Perfect Lotion Bottles?

{acf_ideal_applications_h2_title}

{acf_ideal_applications_application_intro}

Bespoke Lotion Bottle Solutions: Your Vision, Realized

Transform your unique vision into a market-ready reality. Our comprehensive OEM & ODM customization services for lotion bottles empower you to tailor every detail—from material and shape to the dispensing experience—creating a signature packaging solution that perfectly embodies your brand.

Fast & Flexible Customization, Made Simple.

{acf_packaging_suggestions_h2_title}

Quality & Reliability: Testing for a Perfect Dispensing Experience

Pump Performance & Life Cycle Test

We subject our lotion pumps to thousands of automated actuation cycles to assess their durability and performance over time. This test measures the smoothness of the press and the consistency of the output, ensuring a reliable and satisfying user experience throughout the product’s lifespan.

Leakage & Seal Integrity Test

Every bottle and closure combination undergoes stringent leakage tests, often under vacuum conditions. This ensures a perfect, airtight seal that prevents product leakage during shipping, travel, and everyday handling, safeguarding your product and brand reputation.

Formula Compatibility Test

A critical step where we test our packaging materials (PET, HDPE, Glass) against your specific lotion formula or a chemical simulant. This ensures there are no adverse reactions like discoloration or material degradation, guaranteeing your formula’s stability, safety, and efficacy over time.

Drop & Impact Resistance Test

To simulate real-world accidents in environments like the bathroom, our bottles are subjected to standardized drop tests from various heights. This verifies the structural integrity of the packaging, ensuring it withstands accidental impacts without shattering, cracking, or leaking.

Dimensional Accuracy & Fit Test

We use precision instruments to measure key dimensions like the bottle’s neck thread and the cap’s inner diameter. This guarantees a perfect assembly fit between the bottle and its closure, which is fundamental to preventing leaks and ensuring a high-quality feel.

Lotion Bottles: Your Sourcing & Technical Questions Answered

What is the best material for lotion bottles, PET or HDPE?

It depends on your brand’s aesthetic and formula. PET is known for its glass-like clarity and is great for showcasing your lotion’s color and texture. HDPE is typically opaque or translucent, offers excellent durability, and has a softer, more squeezable feel. Both are highly recyclable.

How do you ensure your lotion pumps don't clog with thicker creams?

We offer specialized high-viscosity lotion pumps with wider internal mechanisms and actuators. We recommend a formula compatibility test, where we test your specific lotion with our pump options to find the perfect match that guarantees smooth, clog-free dispensing.

What is the MOQ for a custom-colored lotion bottle?

The Minimum Order Quantity (MOQ) for custom color matching typically starts at 10,000 units. This can vary based on the bottle size and material. For a precise quote, please contact our team with your Pantone color code and project details.

Are your lotion bottles available in PCR (Post-Consumer Recycled) versions?

Yes, absolutely. Most of our PET and HDPE lotion bottle designs are available with high percentages of PCR content. This is a key part of our commitment to sustainability and an excellent way for your brand to appeal to eco-conscious consumers.

Can I get samples to test with my lotion formula?

Yes, we strongly encourage it. We can provide stock samples of our bottles and pumps so you can conduct thorough compatibility and performance testing with your unique formula. This ensures the packaging you choose performs flawlessly before you commit to a full production run.