Wholesale & Custom Foam Pump Bottles for Innovative Formulations

Explore Our Foam Pump Bottles Collection

Not finding what you're looking for?

Contact our consultants for more available products.

The Power of Foam: Elevating Your Product Experience

Foam pump bottles are more than just dispensers; they are a sophisticated packaging solution that enhances product efficacy, optimizes usage, and provides a delightful sensory experience. Explore the distinct advantages our foam pump bottles bring to your brand and your customers.

Luxurious & Efficient Foam Generation

Our high-quality foam pumps are engineered to transform liquid formulations into a rich, stable, and consistent foam with a single press. This not only creates a luxurious sensory experience but also ensures less product is needed per use, leading to extended product life and better value for consumers.

Optimized for Gentle & Specialized Formulations

Ideal for delicate facial cleansers, baby products, and sensitive skin formulas, foam pumps avoid the need for irritating foaming agents in the product itself. They deliver a soft, airy application that is gentle on skin, enhancing the efficacy and appeal of specialized liquid concentrates.

Enhanced Hygiene & Direct Application

Foam is ready for direct application without needing to be lathered, promoting better hygiene as it minimizes touching surfaces. The controlled foam dosage also ensures a cleaner, less messy dispensing experience, making it perfect for bathroom and kitchen environments.

Distinctive Market Appeal & Brand Differentiation

Standing out on the shelf is crucial. Foam pump bottles offer a unique and modern dispensing method that immediately conveys innovation and premium quality. This distinct advantage allows your brand to differentiate itself, attract discerning customers, and communicate a superior product experience.

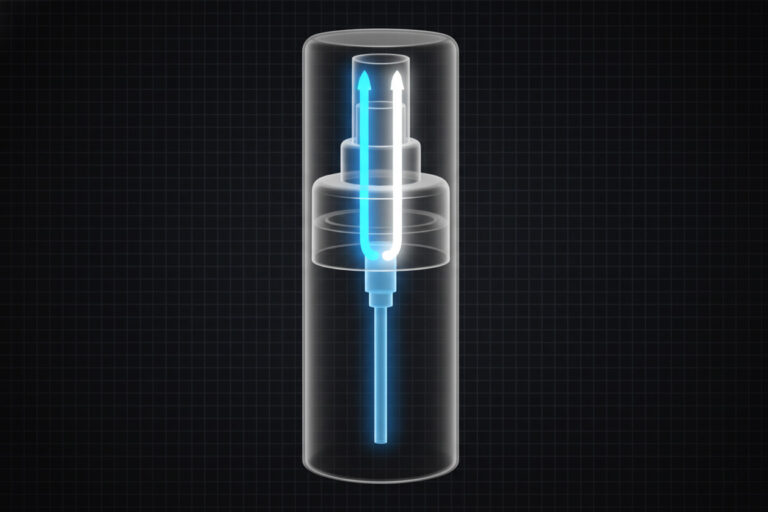

The Ingenious Mechanics: How Our Foam Pumps Create Luxury

The magic of a foam pump lies in its precision engineering, effortlessly transforming liquid into a rich, stable lather with a single press. Far from a simple dispenser, our foam pumps incorporate ingenious mechanics that precisely blend air and liquid, ensuring a consistently luxurious and efficient foam delivery every time.

Precision Dosing & Air Induction System

Our foam pumps feature a meticulously calibrated piston chamber that draws a precise, pre-measured amount of liquid formulation, simultaneously with a specific volume of air through a dedicated induction port. This crucial first step ensures the perfect ratio of liquid to air for optimal foam quality and consistent dosage per pump.

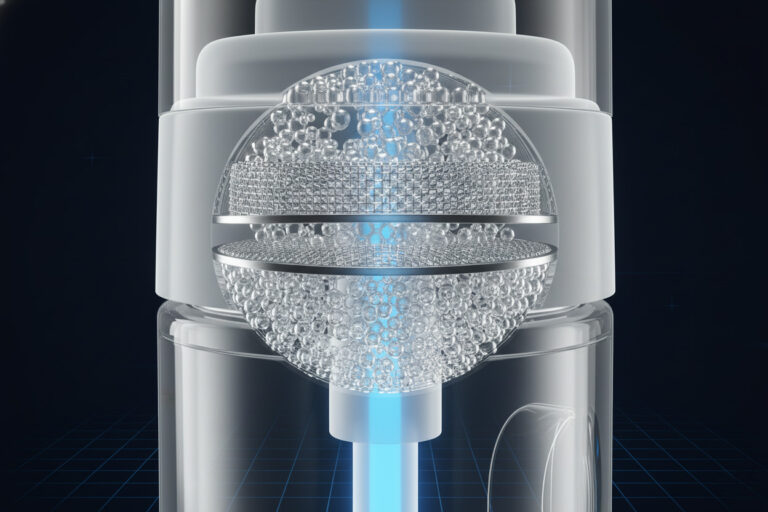

The Dual-Mesh Foam Mixing Chamber

This is the ingenious heart of the foam pump. The accurately dosed liquid and air are forced under pressure through a unique dual-mesh (or multi-mesh) screen system within a specialized mixing chamber. These ultra-fine meshes dynamically agitate the mixture, creating hundreds of tiny, stable bubbles that emerge as rich, ready-to-use foam.

Ergonomic Actuator & Durable Spring Mechanism

Beyond foam generation, the user experience is paramount. Our pumps feature an ergonomically designed actuator (press-head) for comfortable, intuitive use, coupled with a robust spring mechanism that provides smooth tactile feedback and ensures the pump consistently returns to its original position. This guarantees reliable performance and durability throughout the product's lifespan.

Need Custom Packaging Solutions?

The Expert's Guide: Critical Factors in Foam Pump Bottle Selection

Foam Quality & Bubble Structure Optimization (Formulation Interplay)

Not all liquids foam equally well with a standard pump. The viscosity, surface tension, and surfactant type/concentration of your liquid formula are paramount. A foam pump doesn’t create foam from nothing; it converts a pre-foaming liquid into a desired texture.

Expert Advice:

- Early Formula Testing: Provide us with your target liquid formulation early. We can conduct compatibility and foaming tests with various mesh sizes and pump designs to achieve your desired foam consistency (e.g., airy, dense, quick-breaking).

- Viscosity Sweet Spot: Ensure your formula falls within the optimal viscosity range for foam pumps; overly thick or thin liquids will yield poor foam.

- Surfactant Balance: Advise on how your surfactant system impacts foam stability and texture, which we then match with pump desig

Pump Head Actuation & Return Force Consistency

A foam pump should feel consistent, smooth, and return reliably after each press. Poorly designed springs or misaligned internal components can lead to a ‘sticky’ feel, slow return, or even pump failure, frustrating users.

Expert Advice:

- Calibrated Spring Tension: We select springs with precise tension to ensure a comfortable, consistent press and quick return for hundreds of thousands of cycles.

- Ergonomic Design: The actuator’s shape and material are chosen for optimal finger comfort and grip, even with wet hands.

- Longevity Testing: Our pumps undergo rigorous life cycle testing (e.g., 10,000+ presses) to guarantee long-term reliability without degradation in performance.

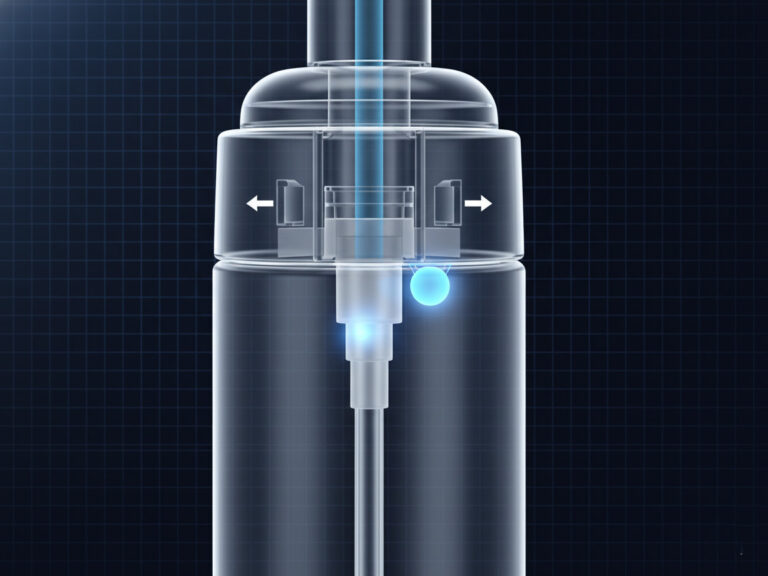

Air Venting & Priming Efficiency for Initial Use

For a foam pump to work, it must first be “primed” (filled with liquid) and have an efficient air vent. A poorly designed venting system can lead to slow priming, ‘false’ pumps (only air comes out), or even product backflow if not designed correctly for the liquid’s specific properties.

Expert Advice:

- Optimized Venting: Our pumps feature precisely engineered air vents that allow for rapid and efficient priming, ensuring foam is delivered almost immediately on first use.

- Anti-Backflow Mechanisms: For certain formulas, we integrate one-way valve systems to prevent liquid from returning into the air channel, maintaining hygiene and consistent performance.

- Dip Tube Length: Meticulously adjust dip tube length to ensure minimal residual product and complete evacuation.

Material Compatibility Beyond Chemical (Stress & Environmental)

Besides chemical compatibility, the plastic pump components must withstand physical stress from repeated pressing and environmental factors like humidity and temperature fluctuations in a bathroom. Certain plastics can warp or degrade under these conditions.

Expert Advice:

- Robust Polymer Selection: We utilize high-grade, stress-resistant polymers (e.g., PP, PE) for critical internal pump components, ensuring dimensional stability and long-term durability.

- UV & Temperature Resistance: If the product is exposed to light or varying temperatures, we recommend materials and additives that resist UV degradation and maintain integrity across temperature ranges common in storage and consumer use.

- Gasket & Seal Material: Critical sealing components are chosen for their resilience against both formula and environmental factors, preventing leaks and air ingress.

Ready to Create Your Perfect Foam Pump Bottles?

{acf_ideal_applications_h2_title}

{acf_ideal_applications_application_intro}

Bespoke Foam Packaging: Tailored to Your Brand & Formula

Your innovative formula deserves packaging that delivers a flawless foam experience. Our comprehensive OEM & ODM customization services allow you to tailor every aspect of your foam pump bottle—from the internal foam engine to the external aesthetics—ensuring it perfectly represents your brand and delights your customers with every press.

Fast & Flexible Customization, Made Simple.

{acf_packaging_suggestions_h2_title}

Quality Assured: Testing for a Flawless Foam Experience

Foam Quality & Density Analysis

This is our most critical test. We use your specific formula (or a chemical simulant) to analyze the foam generated by our pumps. We measure bubble structure, foam density, and stability over time to ensure the pump engine is perfectly matched to your liquid, delivering the exact luxurious and consistent foam texture your brand requires.

Pump Actuation & Life Cycle Test

Our foam pumps undergo extensive life cycle testing, where they are actuated thousands of times by automated equipment. We measure actuation force, spring return speed, and overall mechanical durability to guarantee a smooth, effortless press and long-lasting, reliable performance throughout the product’s entire lifespan.

Priming & Dispensing Consistency Test

A great user experience starts with the very first pump. We test how many presses are required to “prime” the pump and begin dispensing foam. We also measure the output volume and foam consistency over multiple strokes to ensure a frustration-free initial use and a predictable, accurate dose every time.

Formula & Spring Compatibility Test

To prevent long-term failure, we conduct compatibility tests between your formula and the pump’s internal components, especially the metal spring. This crucial step ensures there is no corrosion or material degradation over time, safeguarding your formula’s purity and the pump’s mechanical integrity.

Leakage & Seal Integrity Test

Every bottle and pump combination is subjected to rigorous leakage tests under vacuum pressure and in various orientations (e.g., sideways, upside down). This ensures a perfect, airtight seal at the neck, guaranteeing your product is safe during shipping and remains secure in your customer’s home, gym bag, or travel kit.

Foam Pump Bottles: Your Technical & Sourcing Questions Answered

What kind of liquid formulations work with a foam pump?

Foam pumps are specifically designed for liquids with a water-like viscosity. They will not work with thick gels, creams, or lotions. The formulation must also contain surfactants (foaming agents) that are compatible with the pump mechanism. We strongly recommend providing us with your formula for compatibility testing.

Can the foam texture (e.g., density, richness) be customized?

Yes, absolutely. This is a key area of our expertise. By adjusting the internal pump engine—specifically the mesh screen density and the air-to-liquid ratio—we can significantly influence the resulting foam texture. We can work with you to engineer a pump that produces your desired sensory experience, from a light, airy foam to a dense, rich lather.

My new foam pump bottle isn't working on the first few presses. What should I do?

This is normal and is called “priming.” The pump needs to evacuate the air from the system before it can draw up liquid. Please press the pump head repeatedly (usually 10-15 times) until the foam begins to dispense. This only needs to be done on the very first use.

Are foam pump bottles a sustainable or eco-friendly option?

Yes, they contribute to sustainability in several ways. Firstly, they often lead to reduced product consumption, as a small amount of liquid creates a large volume of foam. Secondly, they are ideal for concentrated formulas, which reduces water usage and shipping footprint. Lastly, we offer foam pump bottles made from widely recyclable materials (like PP) and high-content PCR (Post-Consumer Recycled) plastic.

What is the Minimum Order Quantity (MOQ) for custom foam pump bottles?

Our standard MOQ for foam pump bottles is typically 10,000 units. This can vary depending on the complexity of the customization (e.g., custom color, exclusive mold development). We recommend contacting our team with your project details for a precise quote.

Can I receive samples to test with my own formula?

Yes, we strongly encourage it. Formula compatibility and foam quality testing are crucial steps. We can provide stock samples of our foam pump bottles for you to conduct thorough testing with your unique formula, ensuring optimal performance before you commit to a full production run.